The slitting method is a mechanical relaxation technique that can determine a single component of residual stress within a material’s thickness. This method is useful in laboratory as it is straightforward, efficient, and results in consistent measurements.

During the process of slitting, a planar slit is made in a material that contains residual stress. As the slit becomes deeper, the deformation near it is measured, indicating the amount of residual stress present perpendicular to the slit plane before slitting.

The slitting technique offers several advantages such as the ability to measure depth beyond 100mm, effectiveness in measuring residual stress gradients, applicability to a wide range of materials, and the ability to provide further research opportunities. It is a relatively quick and cost-effective process that allows for cross-comparison of results.

However, there are also several disadvantages to this technique, such as being destructive and laboratory-based, only allowing for uni-axial residual stress measurements, increased uncertainty in surface residual stress measurements, difficulty in application to complex shaped components, and susceptibility to noise and strain response curves.

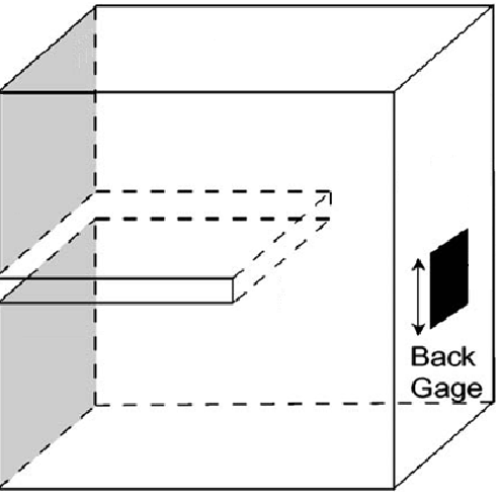

Schematic for the measurement setup

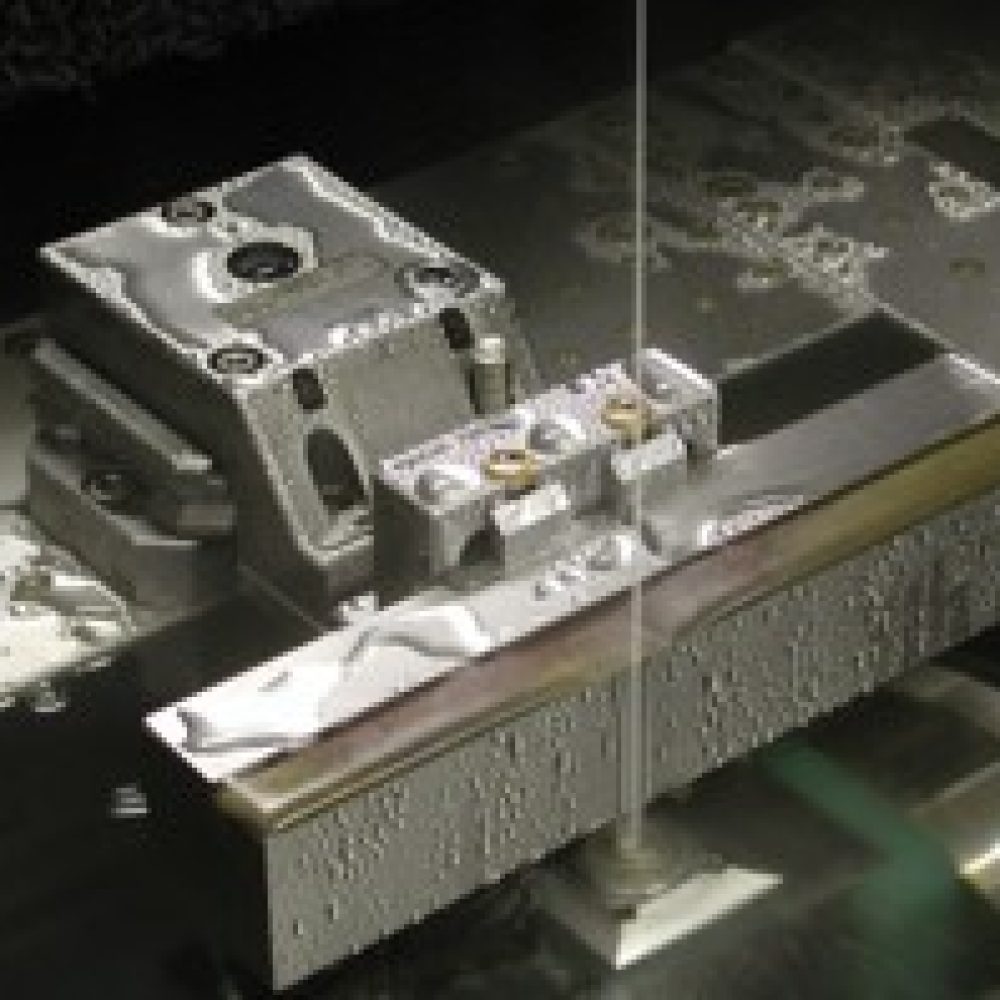

Measurement setup during the cutting

Simultura Material Technologies was established in 2019 to provide consultancy and engineering services.